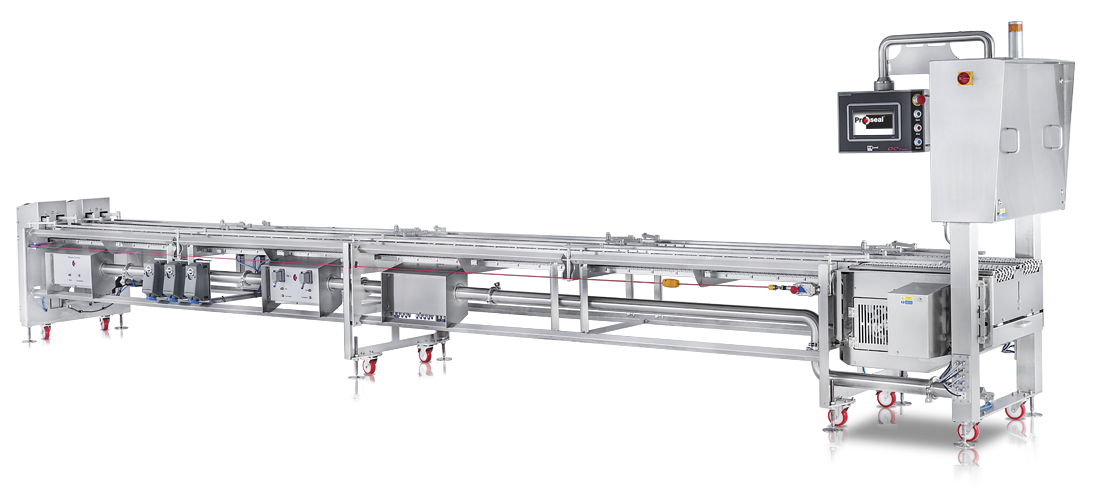

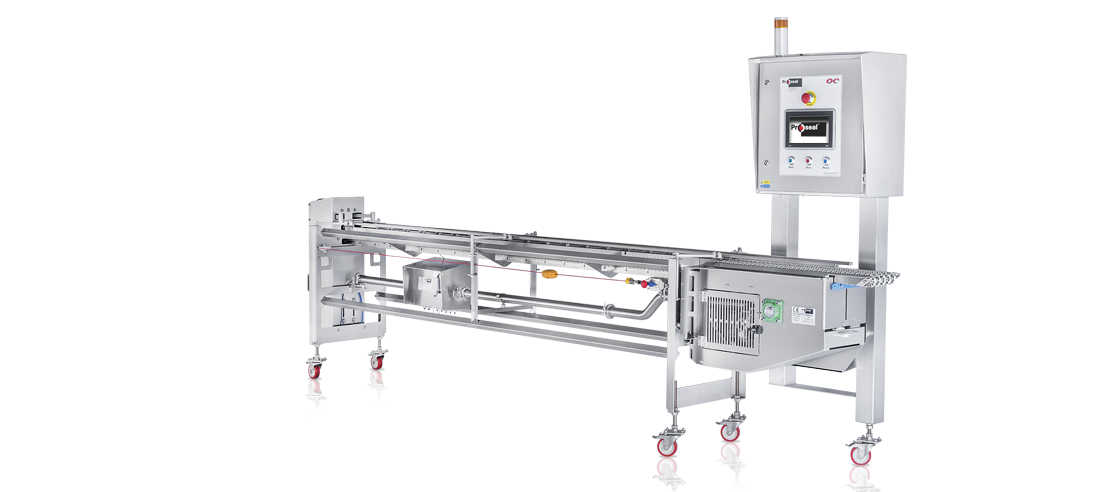

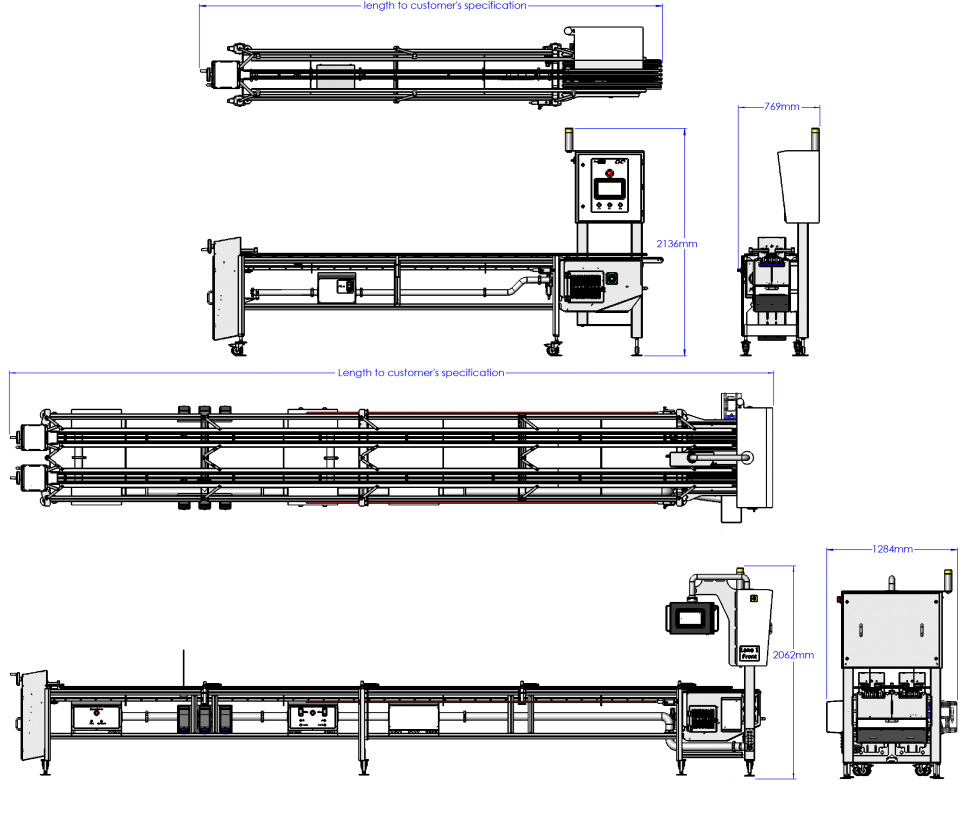

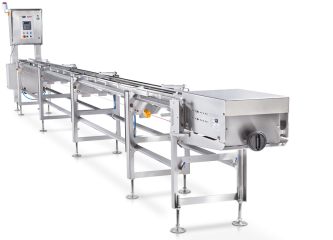

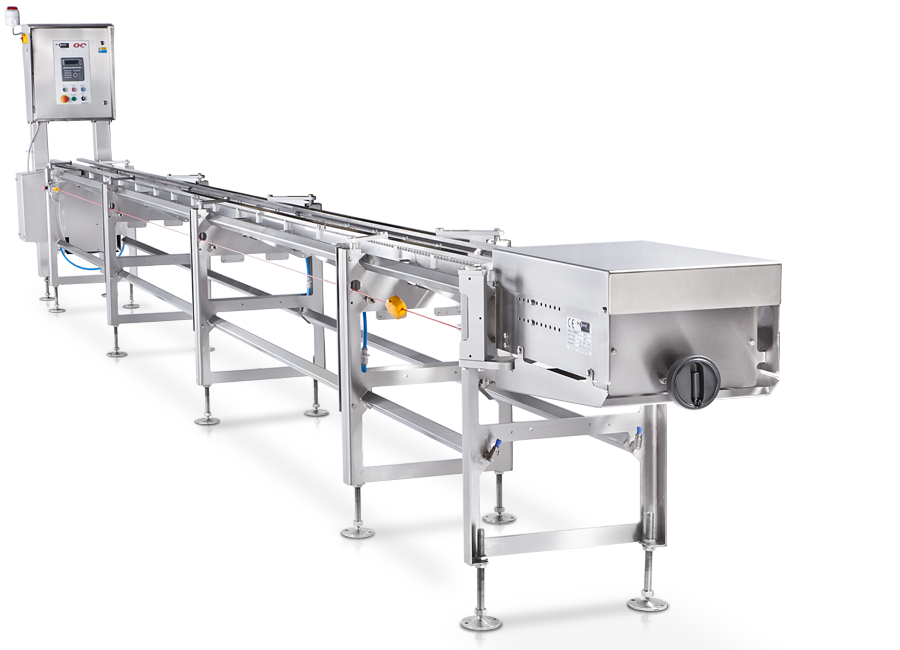

OC Conveyor / Twin

An open-style, linear/twin-lane conveyor with an intelligent filler control system.

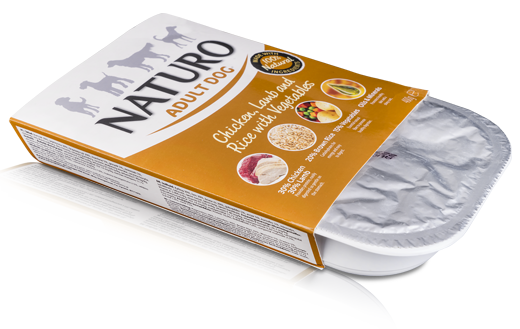

A high throughput modular tray conveyor and filler control system, available in either single or twin-lane configuration. This range is designed to integrate with auxiliary equipment (such as tray de-nesters, fillers, multi-head weighers) and to feed filled trays seamlessly into any in-line automatic machine - including the GT0, GT1, GT2 or GT3 - to create a fully automatic production line.

Easily integrated with other production line equipment

It has throughput speeds of up to 60 packs per minute in continuous mode and 45 packs per minute in indexing mode with 0.5 second fill dwell in single lane, and 120 packs per minute in continuous mode and 90 packs per minute in indexing mode with 0.5 second fill dwell in twin lane.

The OC Conveyor/Twin provides the flexibility required by food producers looking for a fully automated, turnkey production line with rapid product and tray type changeover in under 5 minutes.