09/06/2015

-

- Markets

- Machine Range

- Capabilities

- Innovations

09/06/2015

The latest technologies to maximise speed and efficiency in the packing of soft fruit will be demonstrated on the Proseal stand at this year's Fruit Focus.

The company, the leading supplier of tray sealing solutions to the soft fruit industry, will showcase a variety of advanced technical enhancements – E-Seal®, Pro-Motion and I-Film – which deliver significant energy savings and increased throughput. Importantly, for the benefit of existing Proseal customers, these features can be easily added to current machines.

"One of the most important aspects of the design of any new Proseal model is to ensure that it has the ability to be upgraded as new technologies and enhancements become available," explains Tony Burgess, the company's head of sales and control systems.

"The easier option would be to try to sell a new machine every time, but we believe it is important to give our customers the option of continuing to get the very best out of their existing equipment."

E-seal® delivers high quality seals while achieving a 92% reduction in energy usage. Pro-Motion, which uses following motion and intelligent buffering technology to enable trays to feed continuously into the sealer without stopping, provides a 30% increase in production throughput. I-Film stores the film settings for individual trays in the tray sealer's memory to ensure the accurate positioning of pre-printed film after every tool change.

Proseal's comprehensive tray sealer range comprises both semi-automatic and automatic models, suitable for a wide variety of soft fruit production and packing line requirements, with sealing speeds of up to 210 packs per minute.

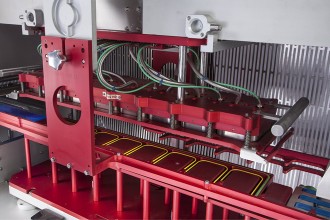

The company's automatic inline tray sealers incorporate a servo-driven infeed conveyor and high accuracy tray positioning system for high throughput speeds. An intelligent film feed system ensures full control of the sealing operation for excellent seal quality, with easy film threading and dynamic control of the movement of the film throughout the film feed cycle in order to maintain constant tension and avoid film snapping.

The machines offer a rugged construction manufactured to food industry approved hygiene standards with full wash-down protection. Proseal's pioneering advanced lightweight and high strength 'Auto Tool' connection system enables tool changes to be carried out in around five minutes. Downtime is also minimised by the use of quick-change conveyor belts, and an auto-lock film reel holder. The machines' practical designs are further enhanced by situating the electrical controls above the sealing area, which also allows for safe access.

User-friendly menu-driven control panels enable easy set up and operation, which can be remotely accessed and controlled. The screen also provides detailed production data, production monitoring and full diagnostics. Full double-sided operation is provided by a swing arm control interface for enhanced accessibility.