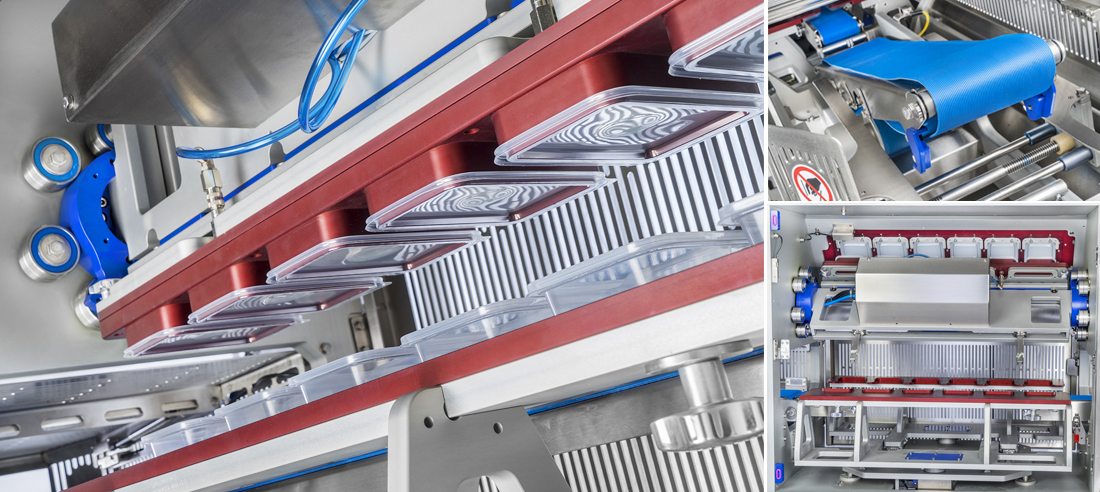

GT1-Lid

Fully automatic, in-line, lid placing de-nesting and tamping system designed to cut labour costs.

This is the first of our GTLid machine range. The GTLid range is based on the knowledge and experience gathered from our world-renowned GT tray-sealing machine series and the key principles found within. Some of these key principles include an integral space-saving design, an impressive 5-minute tool change time, our Promotion pause-free tray spacing and our Eseal® 'all-electric' seal actuator.

The GT1-Lid system is designed to accept trays from any conveyors, clip lids on to film-sealed trays, and take trays directly from a filling conveyor when no film lid is required. Through using the aforementioned features to avoid any loading errors, the GT1-Lid system can be fully integrated with any other in-line equipment including upstream tray-sealing machines.