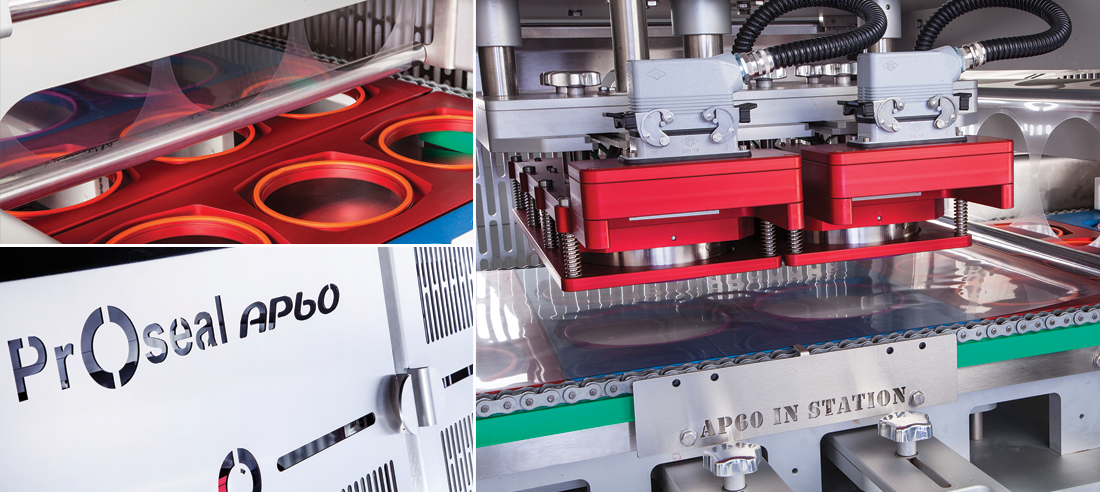

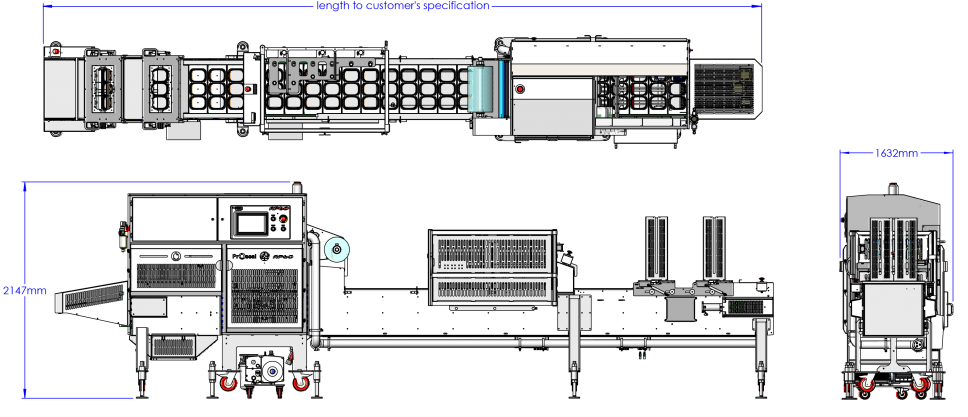

AP60

Linear conveyor tray sealing system capable of sealing up to 240 packs per minute.

The AP60 provides the flexibility required by food producers looking for a fully automated turnkey production line. The customer can specify the length and width of the indexing conveyor to accommodate their tray de-nesting and filling requirements.

Optional ‘free-flow’ gas flush Modified Atmosphere Packaging (MAP) available for extended shelf life.

Easily integrated with other production line equipment