-

- Markets

- Machine Range

- Capabilities

- Innovations

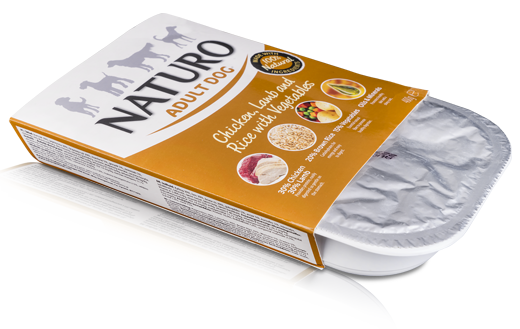

Atmospheric seal utilising any film type including ventilated, micro perforated, or hermetic seal. The pack is simply sealed to extend shelf life without any MAP (Modified Atmosphere Packaging) however,the speeds at which this process runs means the technology comprised in a Proseal machine is far from 'simple'. Often used for produce and soft fruit where speed is key.

This process extends shelf life making the product better suited to the retail transit chain, while ensuring safety and freshness for the end user by considerably delaying the growth of bacteria. This process is also beneficial for aesthetic reasons, such as preserving the look of sliced produce where gas mixtures can help stave-off enzymatic browning or to retain fresh colours in applications such as red meat. Proseal machinery is able to reach a 1% residual gas target without the use of vacuum systems and tooling.

This sealing technology means the product can be sealed tightly with a stretch film in a shallow base tray, allowing vertical shelf stacking and minimal product movement, this improves the aesthetic appeal and customer shopping experience as it can make for better product visibility on-shelf. This style reflects that of product that is shrink wrapped, like meat and produce regularly is, however, it is fully hermetically sealed (air and water tight) around the tray flange as has the eco benefit of cutting down plastic use as unlike shrink wrap the film does not have to go all the way around the pack.

Vacuum only, or partial vacuum. Typically used prior to a post seal process such as retort.

Skin packaging has become increasingly popular as, in particular for red meat applications, it greatly extends shelf life without the use of gas and allows for vertical display on the retailer shelf. Although the technology for skin packaging has existed for a long time, Proseal has invested many resources into developing this even further. We have brought skinning into the mainstream market making this style of packing easily available to all major food manufacturers.

Proseal has three categories of Skin Packing, differentiated by the differing amount of product protruding above the tray flange.

Skin Plus - 50mm of product protruision above the tray flange height.

Skin Deep packaging allows 100mm of product protrusion above the flange of the tray enabling large products to be skin packaged.