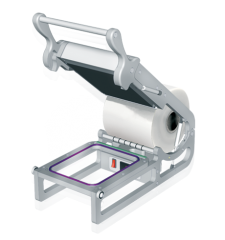

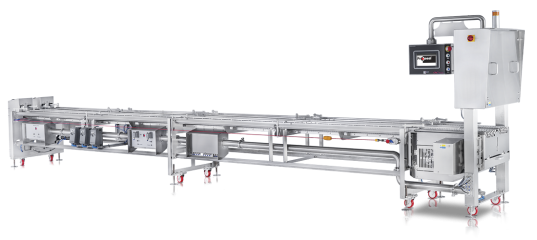

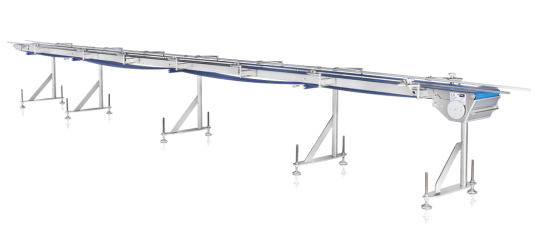

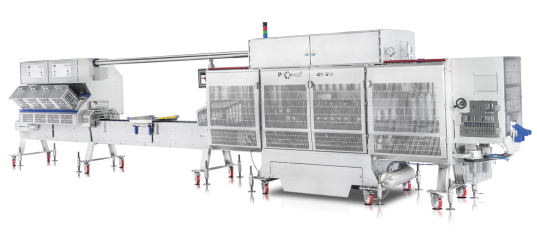

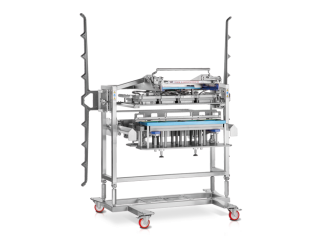

Machine Range

Our tray sealing machine range

'Offering customers the complete packaging solution, Proseal manufactures an extensive range of manual, semi-automatic and fully-automatic tray sealing machines with throughputs from 6 to 240 packs per minute. In addition, all tray sealing machines in our range are capable of modified atmosphere packaging.

Quality, service, precision and rapid response to customer requirements are the core values that we have taken forward into our own machine manufacture.'