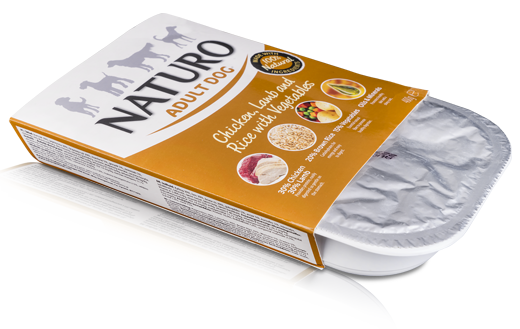

Case Packing Machinery

Proseal's Case Packing machinery range provides the ideal complement to Proseal tray sealing machinery

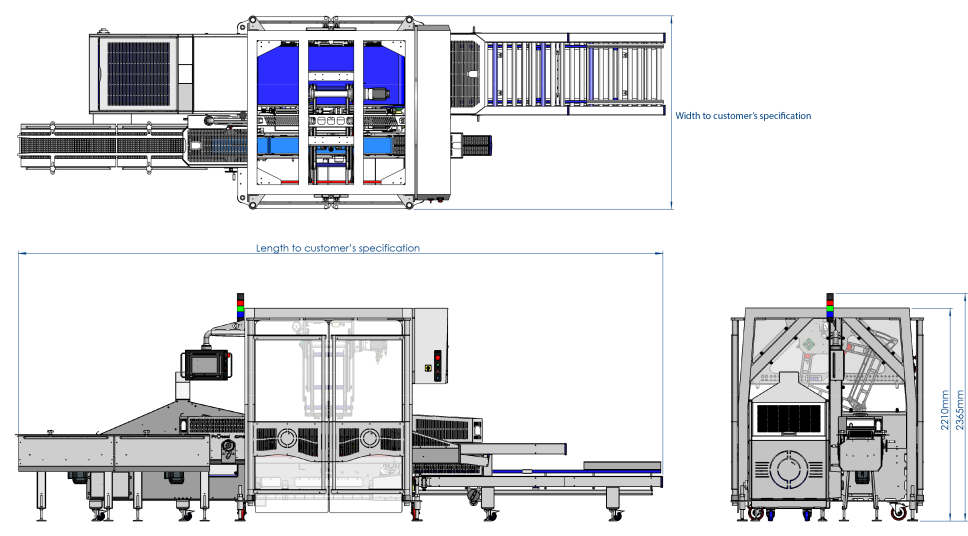

Our philosophy is to complete the modern high-speed packing line with a solution that is cost effective, efficient and delivers exceptional performance within a compact footprint.

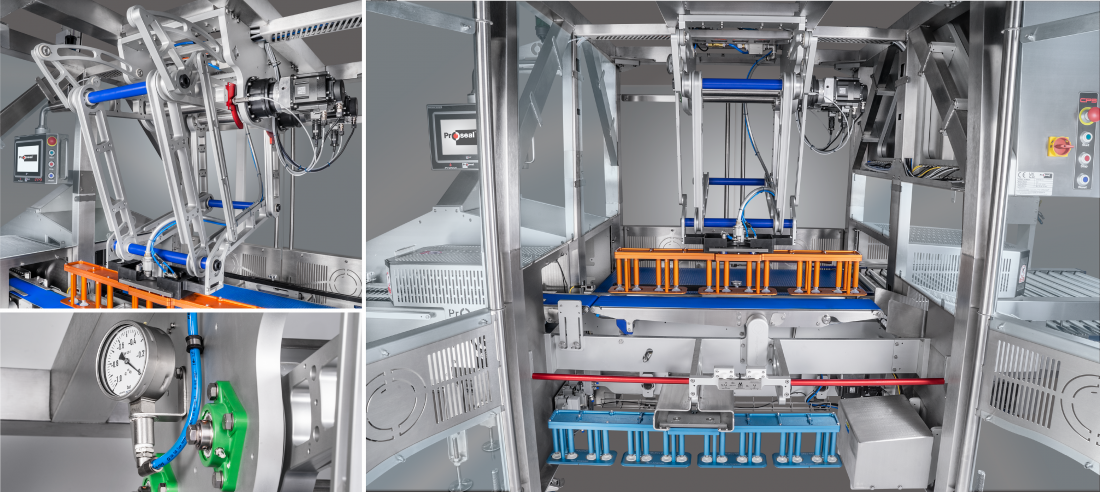

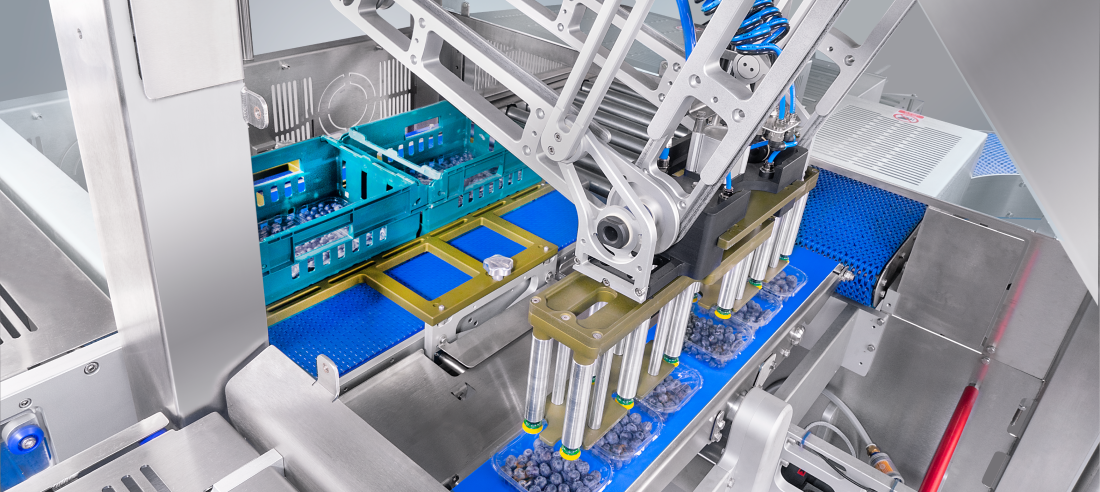

Capable of over 200* packs per minute, the Proseal Case Packing range utilises the latest 2D delta robotic system, which boasts unrivalled flexibility and is adaptable for different tray sizes, configurations and loading formats.

A key feature of this system is the quick-release tooling that significantly reduces product changeover times, which along with an intuitive recipe-based control system, allows product changeovers to be completed in less than a minute.

At the core of the design is our tried and tested ProMotion™ intelligent, non-stop, tray spacing system. With millions of miles now on the clock in production environments, it is an obvious technology to utilise for this crucial part of the packaging process. Allied to this efficiency principle is the common use of Proseal spare parts, shared across our tray sealing and case packaging range, and other industry leading Proseal features.

With a number of options within the range, the Proseal Case Packing machines are capable of packaging any format, including non-tray sealed packaging, from low volume right through to ultra-high-volume production.

*Subject to machine variant/tooling configuration