Standard design features and benefits

ProTest take the guessing out of tray-sealing and peeling;

The ProTest is an automated lid-peeling device, designed to measure and report the resistance offered by the film as it separates from the tray during the moment of lid peeling.

With its easy set-up, the user can specify the strength of peel required for the specific product, process, material or environment of their production facility.

Having a ProTest on site gives up-to-date, line-by-line seal integrity analysis, cutting out the need to send samples off site for costly, third-party testing.

The ProTest is capable of retaining, displaying and outputting test data, allowing the user to export the information. Once exported it’s possible to compare up to five test results against one another simultaneously, in a variety of formats.

Reports are initially generated for review on the machines built-in, 12-inch, high-definition touchscreen. Alternatively, this data can be quickly exported via Ethernet or USB device.

The exported data provides the user with traceability records and assurance of peel strengths maintained throughout production. The understanding of peel strength both before and during the production process can be a priceless tool in solving any seal issues.

ProTest is designed with a user-friendly interface for simple operation. The unit is robust, self-contained and very simple to operate, requiring only 1200mm x 400mm of bench space.

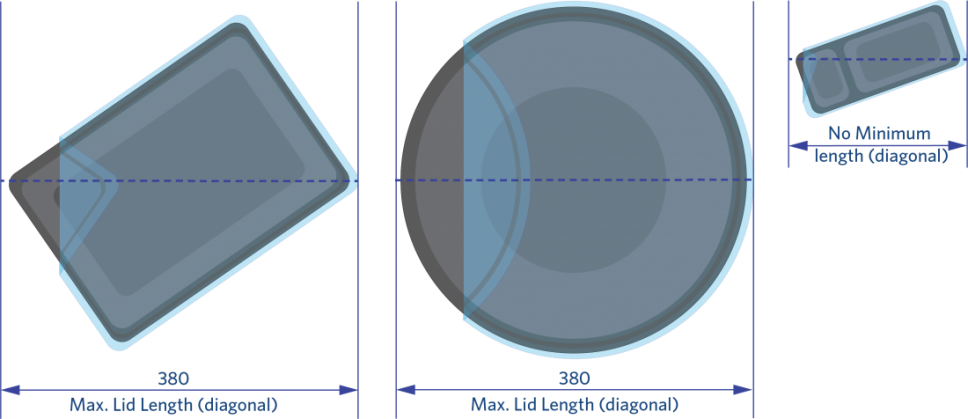

ProTest is designed to be flexible to suit the vast majority of trays used in the market place.

Technical Specification

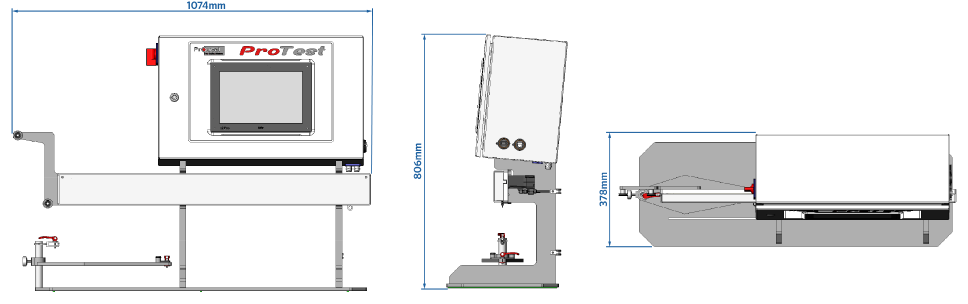

Compact, bench-top testing equipment suited to any working environment.

ProTest Specification

| Height |

806mm |

| Length |

1074mm |

| Width |

378mm |

| Weight |

51kg |

| Electrical Supply |

230V |

Tray Capacity

| Tray Depth Max |

120mm |

| Diagonal Pull Max |

380mm |

ProTest is designed to be flexible to suit the vast majority of trays used in the market place.

The maximum diagonal pull the machine is capable of is a diagonal tray diameter of 380mm. There is no limit to the shape of the tray or how small it can be.

Lid Peeling Defined

A peelability test is achieved in five easy steps:

- Switch on the unit

- Choose which tray from your production you wish to test

- Secure it, using the specially designed film clamp and tray support

- Fill in some details to identify the materials and parameters before testing

- Press Go.

By employing a ProTest unit, the user is able to establish their own Peelability Metrics for the specific tray size, tray material, film, and process.

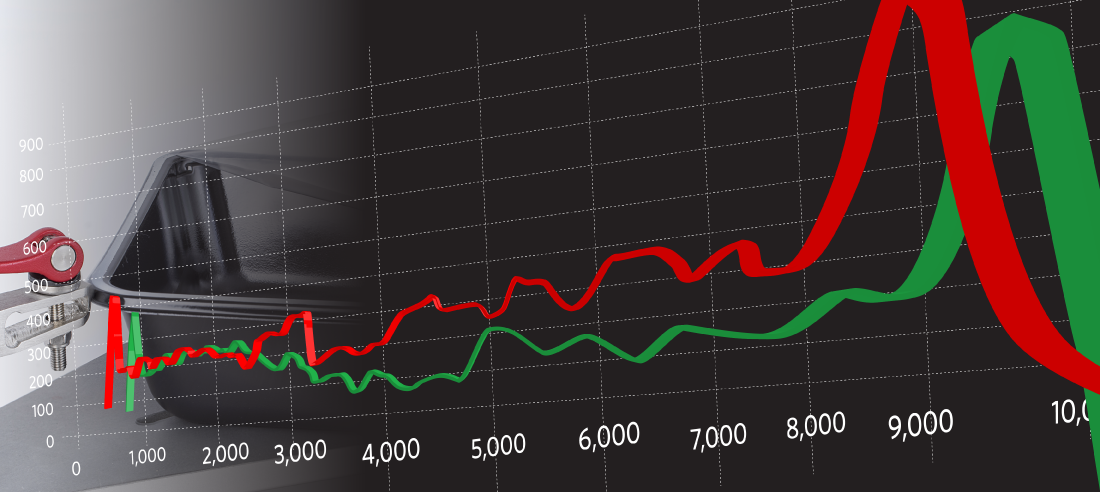

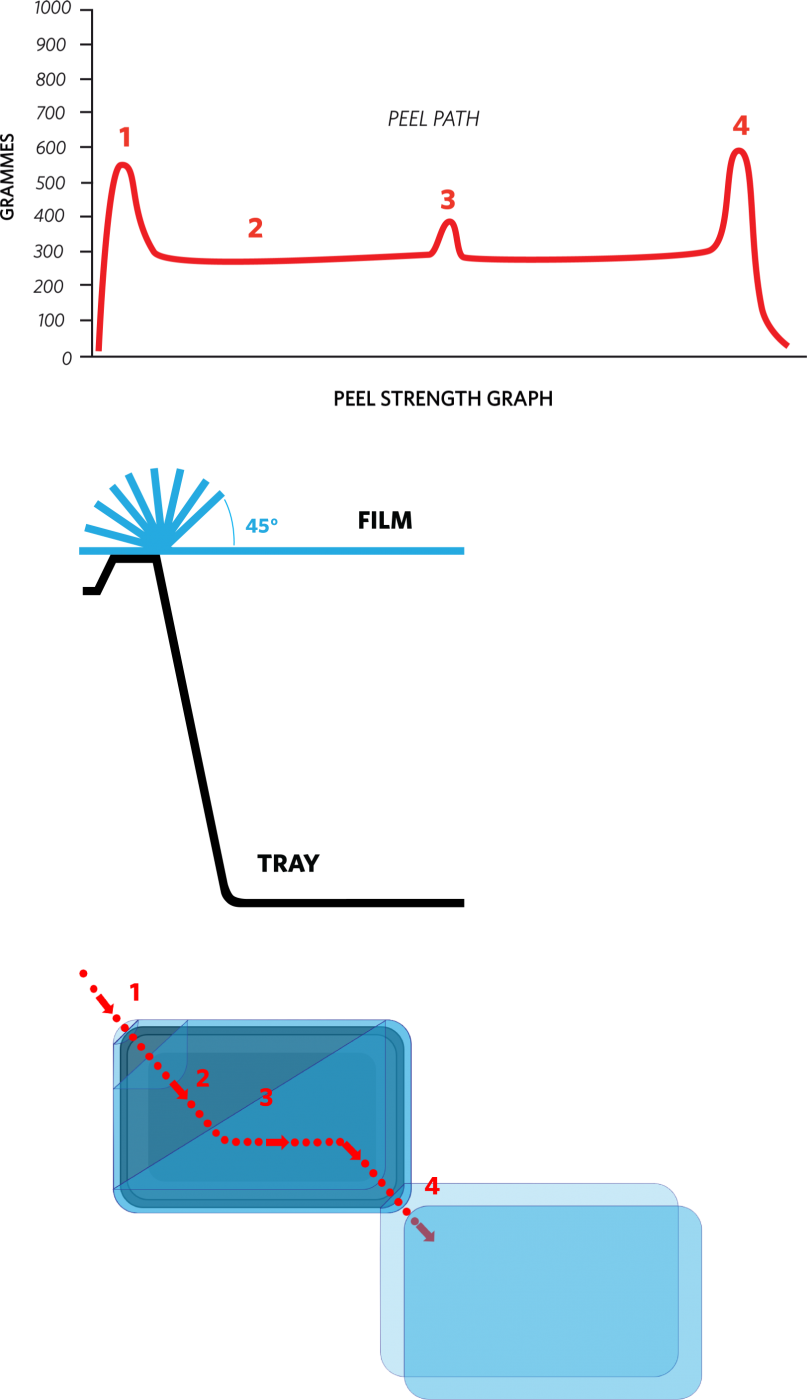

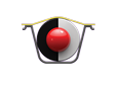

To be able to fully understand the results produced by a ProTest unit, Proseal have established a set of ‘Peelability Metrics’ to break a single peel down into four stages of assessment:

1. PEEL INITIATION (PI)

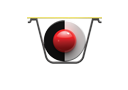

To obtain the initial separation an increased weight of draw is required at a 45 degree angle between the tray and film.

2. PEEL CONSTANT (PC)

A lower weight of draw is required as the film peels along the straight edges of the tray.

3. PEEL CORNER CONSTANT (PCC)

The draw weight increases slightly as the film reaches the corners diagonally across the tray.

4. PEEL END (PE)

This is the last draw of the film which increases as the last corner of bond is separated.