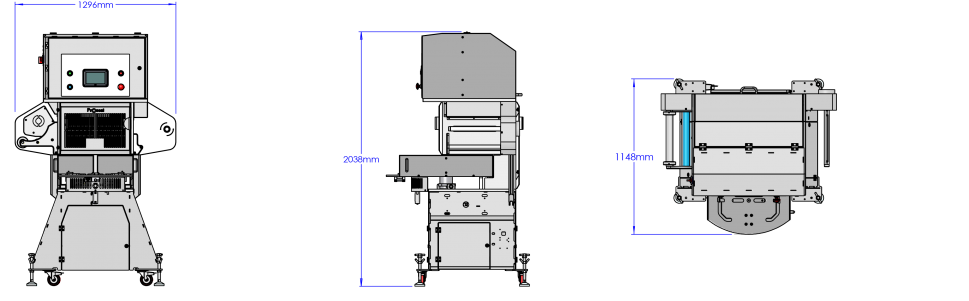

GTRe

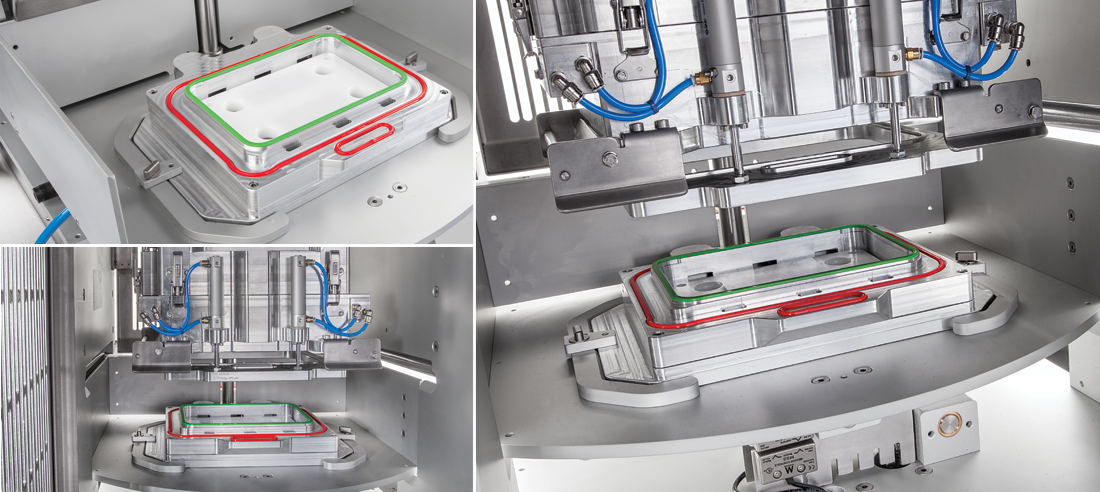

Semi-automatic, two-station, rotary-table, tray sealing machine with full vacuum facility

Capable of sealing up to 20 Vacuum/Gas packs per minute with a 2 impression tool.

At the core of the 'e' design is its flexibility to perform any style of heat seal to a pre-formed tray, be that atmospheric, MAP, VMAP, Skin, Skin Plus, or Skin Deep. Each of these options can be added now or at a later date, or indeed removed as necessary. This flexibility provides the user with the assurance that whatever the latest packaging trend might be, they have equipment suitably geared for the future.