-

- Markets

- Machine Range

- Capabilities

- Innovations

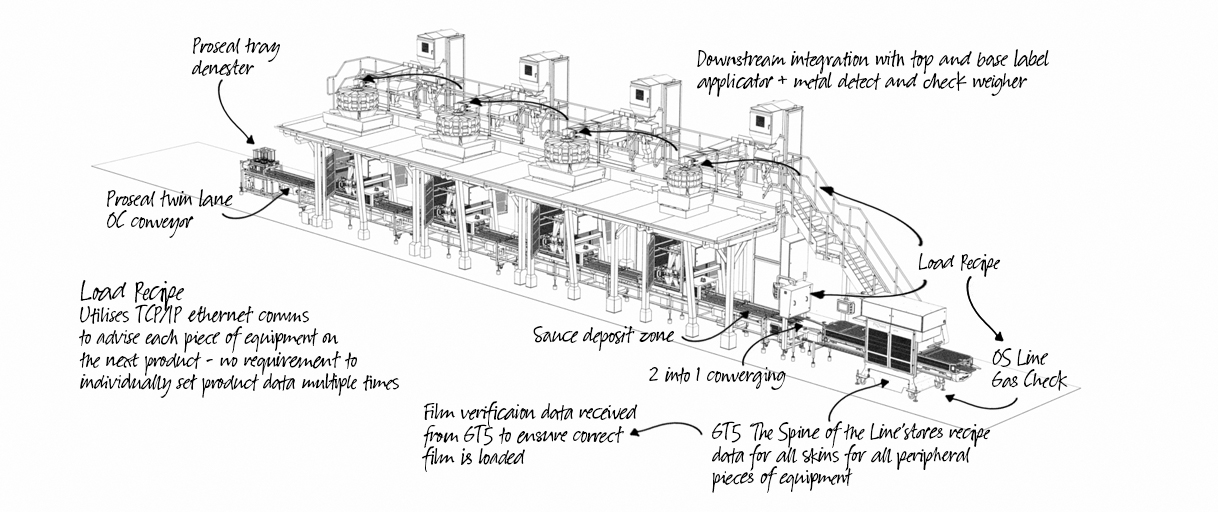

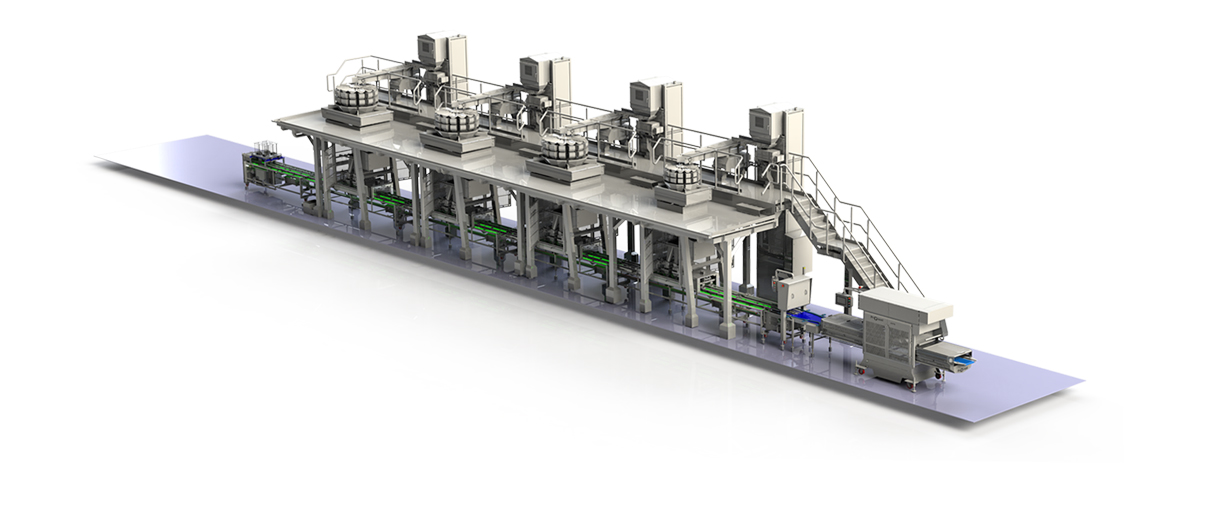

Automatic filling, sealing and Gas Flushing multi component salad bowls

With the increased cost of labour in most countries, many food manufactures are looking to automation to keep costs of running their production down. In this case the customer was producing 5 component ready-to-eat salad bowls. They wanted minimum human intervention by keeping the line setup and changeover times to an absolute minimum, so that a production speed of 60 trays per minute is maximised throughout the production shift with the incorporation of MAP Gas Flush.