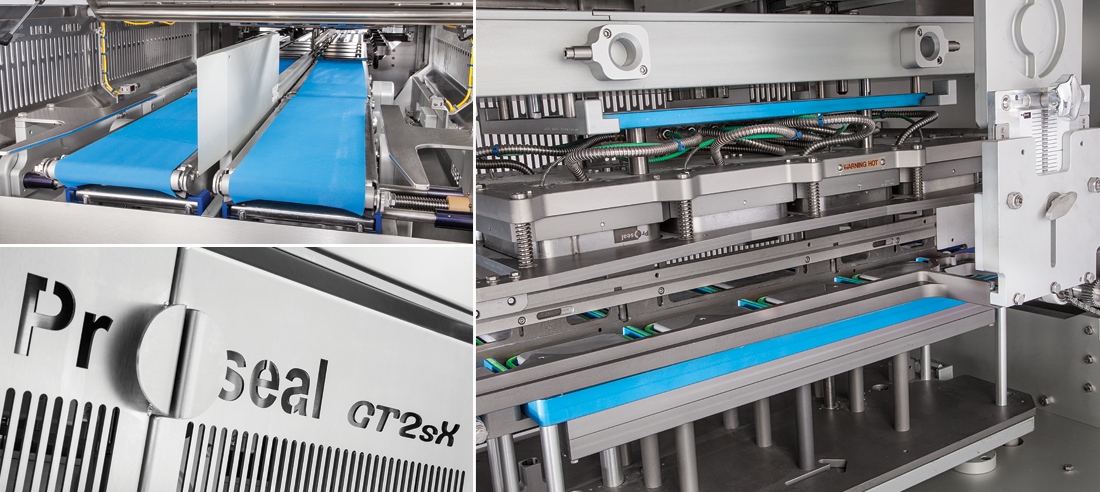

GT2sX / Twin

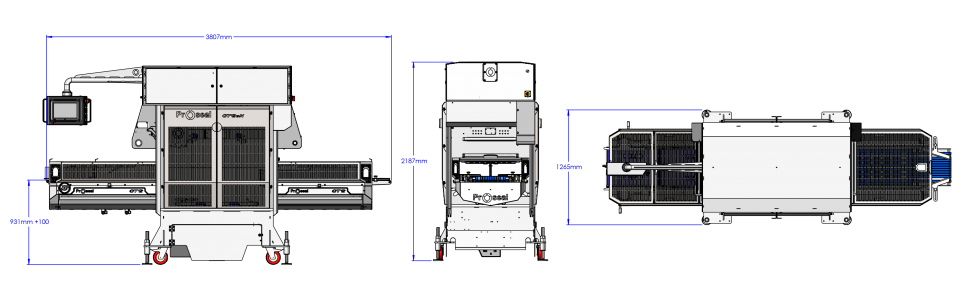

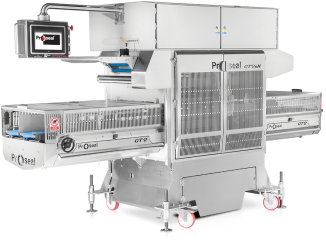

The GT2sX is an automatic, large-capacity, extra-wide, high-speed tray sealing system designed to cut labour costs

With increased production capacity the GT2sX has the ability to take packs up to 400mm wide, long edge leading, into the machine.

Capable of up to 120 Atmospheric packs per minute with a 10 impression tool the GT2sX system is packed with user-friendly benefits including our special lightweight, high-strength tooling.

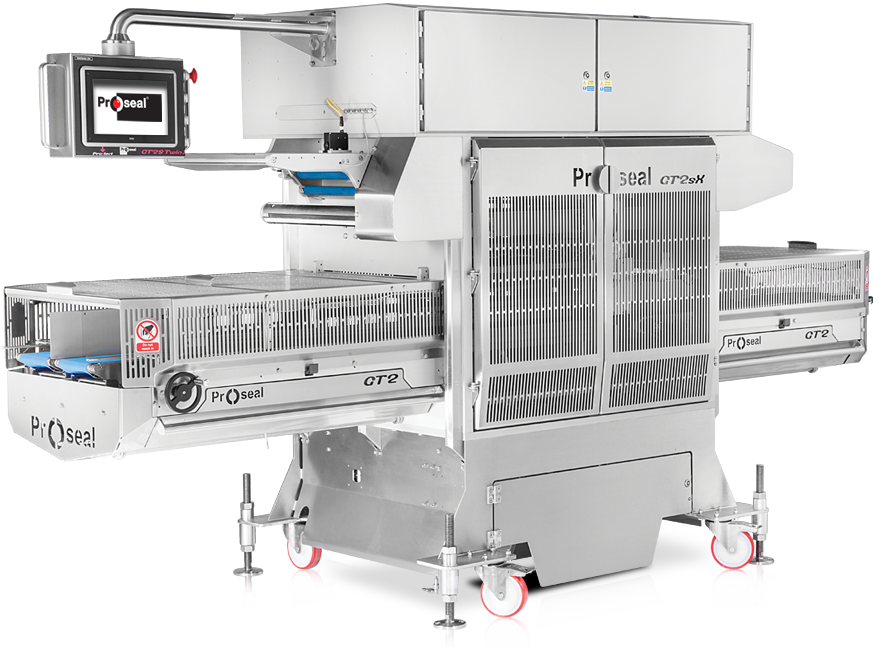

The GT2sX-Twin is a high throughput modular, twin-lane, linear, heat-sealing system. It is designed to run in conjunction with auxiliary equipment such as tray de-nesters, fillers, multi-head weighers and labellers, combining into a stand-alone, fully automatic production line.

Capable of up to 150 Atmospheric packs per minute with a 10 Impression Tool, the GT2sX-Twin system is packed with user-friendly benefits including our unique Promotion modular conveyor system.

Designed to accept randomly spaced trays from any conveyor and can be fully integrated with other line equipment.