25/04/2018

-

- Markets

- Machine Range

- Capabilities

- Innovations

25/04/2018

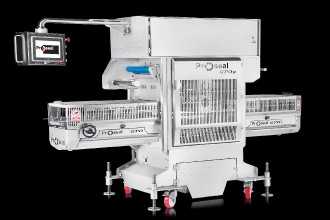

The efficiency, flexibility, and quality of the Proseal tray sealer range are ideally demonstrated by the GT0s, which will be shown at Propak. The GT0s is an automatic, medium- capacity, high-speed, in-line tray sealing system designed to cut labour costs. It combines high throughput with rapid tool-changing and space saving compact design. Optional ‘free-flow’ gas flush Modified Atmosphere Packaging (MAP) available for extended shelf life. Capable of up to 36 Atmospheric packs per minute with a 2-impression tool, the GT0s system is packed with user-friendly benefits including our unique ProMotion modular conveyor system. Designed to accept randomly spaced trays from any conveyor and can be fully integrated with other line equipment. It is packed with many proven functional and reliability benefits.

One of these benefits is Proseal’s E-Seal® technology. This provides an energy efficient system that delivers a high-precision seal with an extremely strong sealing force, ensuring every seal has the tightness and reliability to meet the stringent quality requirements of the retail sector. At the same time, retaining pneumatic functions means the machine can also offer additional benefits such as date coding of pre-printed film.

Equally important, the technology achieves an increase of seal force of 260%, while only consuming 8% of the air of a machine fitted with an equivalent standard pneumatic cylinder. This delivers major energy and cost savings that also have an important impact on a company’s environmental performance and help to meet carbon reduction targets.

Like all Proseal models, the GT0s retains Proseal’s renowned rugged construction to food industry approved hygiene standards with full wash-down protection. Proseal’s established ‘Auto Tool’ connection system enables tool changes to be carried out in around two minutes, while downtime is further minimised by the use of quick-change conveyor belts, and an auto-lock film reel holder. The machine’s practical design is enhanced by situating the electrical controls above the sealing area, which also allows safe access for cleaning.

In addition, the GT0s incorporates a user-friendly menu-driven control panel for ease of set up and operation, which can be remotely accessed and controlled. The screen also provides detailed production data, production monitoring and full diagnostics. Full double-sided operation is provided by a swing arm control interface for enhanced accessibility.